KPZ

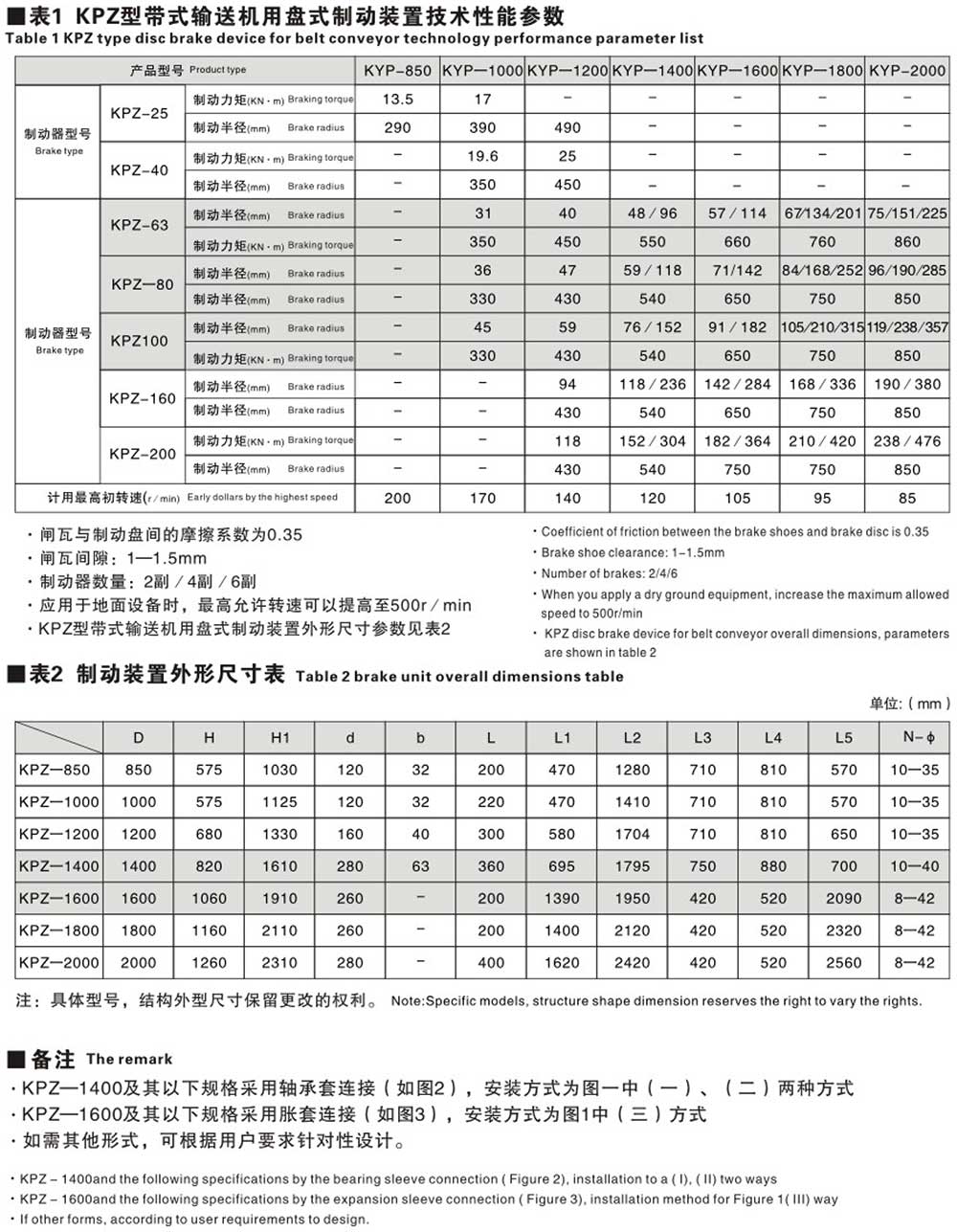

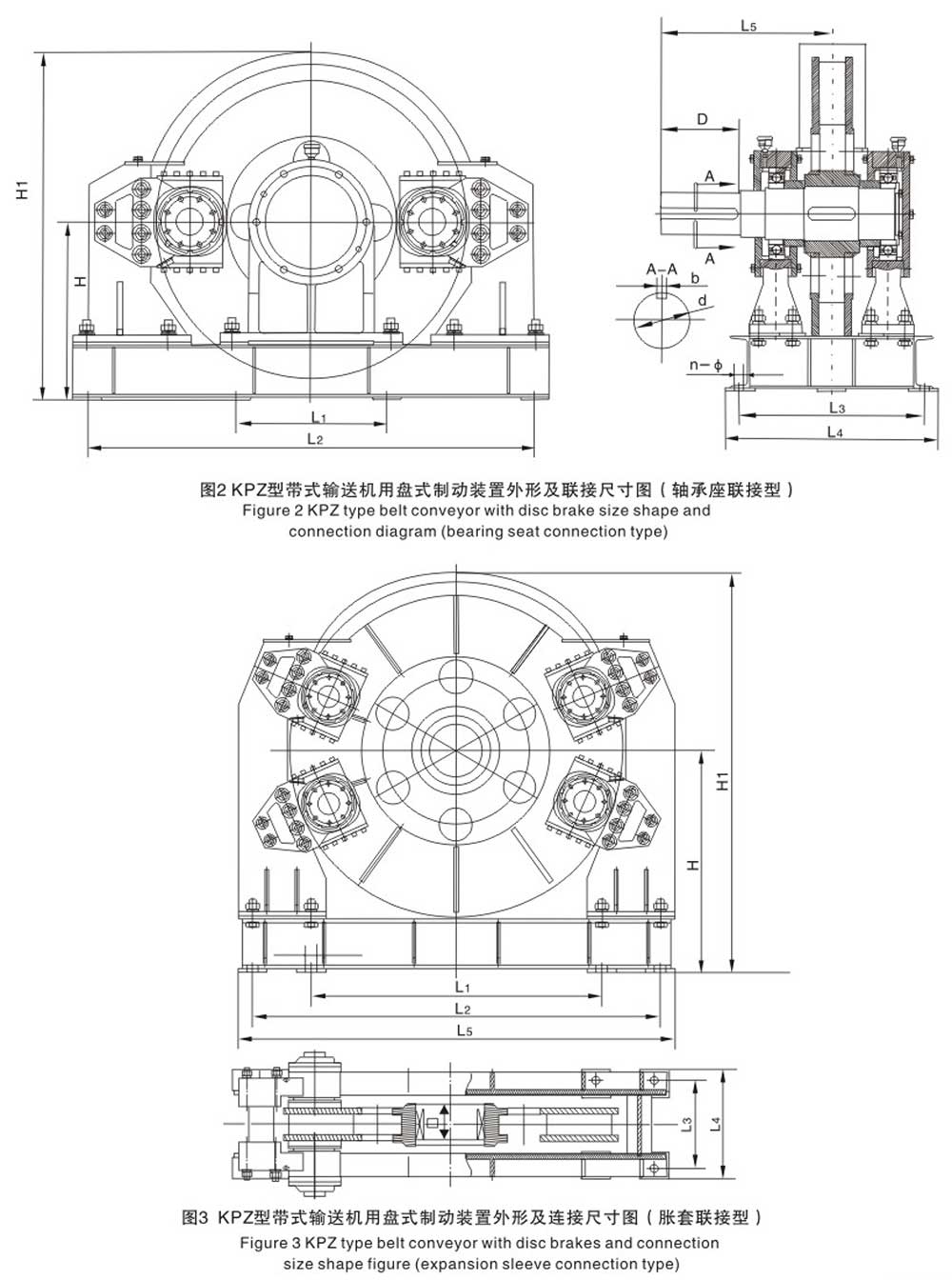

Disc brake device for belt conveyor

Application:

The KPZ controllable disc brake is primarily used at the low-speed end of large belt conveyors, functioning similarly to a safety brake.

The KPZ controllable disc brake is primarily used at the low-speed end of large belt conveyors, functioning similarly to a safety brake.

Due to the high throughput of large belt conveyors, sudden stops are not feasible.

For the high-speed end, braking can be delayed by adjusting the descending valve on the actuator. At the low-speed end, the brake time can be controlled via a PLC (Programmable Logic Controller) managing the hydraulic station, allowing the equipment to stop safely and smoothly in the event of a sudden power failure.

With the electronic control device, the stopping speed of large mechanical and electrical equipment is maintained at 0.05~0.03m/S2.

When the system suddenly loses power, it can still ensure that the large mechanical and electrical equipment slows down and stops smoothly.

The structure is normally closed and the parking performance is reliable.

Hydraulic control system adopts double circuit structure, one use one standby, high reliability.

The ambient temperature is below 40 ° C, the brake is 10 times per hour, the maximum temperature of the disk is not higher than 150 ° C, and no spark is generated.

The operating temperature is -10℃~+40℃.

No significant swaying and severe vibration, shock occasions.

No atmosphere of gas and dust capable of corroding metal.

The altitude of the site shall not exceed 2000m.

Suitable for explosion-proof occasions in coal mines.